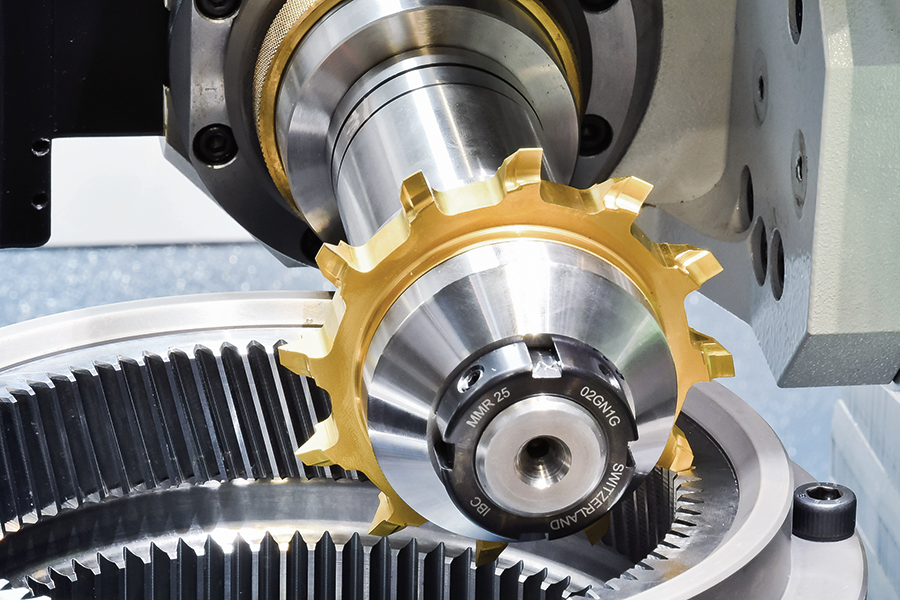

Chamfering and deburring are an essential part of gear production. LMT Tools’ patented ChamferCut technology especially plays an important role when it comes to combining efficiency and quality: over 1,200 different components in some 25 countries are being chamfered and deburred successfully.

After starting with chamfer cutting on involute gears, today all process advantages can also be used with sprocket gears and worm gears, as well as with other gear types. With the newest tools, ChamferCut-CG and ChamferCut-IG, LMT Tools is introducing a new variant of ChamferCut in 2019, again delivering the highest quality results with low tool costs and extremely high productivity.

Precise – reliable – cost-effective. This is chamfering with the patented ChamferCut technology. As component-bound form cutter, ChamferCut allows the chamfering and deburring of gears in a continuous process. A consistently high chamfer quality is possible even in high-strength materials. ChamferCut stands for long tool life, short cycle times and a positive impact on subsequent processes. This reduces the component costs considerably.

The ChamferCut-CG (Collision Gear) also enables users to apply the process on components with interference contours, such as gear shafts.

For this two individual ChamferCuts deburr and chamfer the flanks of the tooth gap one after the other and achieve the well-known quality and process reliability.

From now on internal gears can also be deburred and chamfered with cutting methods: The ChamferCut-IG (Internal Gear) makes this possible for users. For example, manufacturers of planetary gears can now benefit from all cost and quality advantages of the established proven ChamferCut process.

We are be happy to provide you with more information. Together, we develop ideas that make your production more efficient, innovative and profitable. Simply give us a call, send us an e-mail or use the contact form.

LMT Tool Systems GmbH & Co. KG

Segment Verzahnen

Grabauer Strasse 24

21493 Schwarzenbek

Deutschland

T +49 4151 12 - 275