Cylinder Crankcase

Large Volume Production - accurate down to the last micrometer

Accurate Down to the Last Micrometer

Extreme forces are at work inside the cylinder crankcase. The component has to sustain increasing specific forces, such as a high ignition pressure and speed. Only when processed precisely down to the last micrometer can it be guaranteed that the engine is efficient and runs smoothly.

This has the following implications for the cylinder bore: The processing quality required here is almost unparalleled in industrial production. During the process, a defined surface quality and perfect roundness must be achieved. Another challenge in large volume production are nano surface coatings with which an even more compact and lightweight housing can be built. The results very much depend on the precision tools that are used. They must guarantee short processing times as well as a high level of process reliability and quality. To realize this, our engineers are developing custom-fitted tool solutions for processing cylinder bores, flat surfaces and bearing bores. The geometry, cutting material and coating of the indexable insert that are used are matched to the maximum strain. In this way we were able, for example, to improve the cutting speed for roughing cylinder bores or the surface quality of their finish. The LMT Tools experts are able to draw on substantial knowledge in processing bearing bores. The tools are equipped with automatic blade compensation – the process is carried out without interruption, thus lowering cycle times.

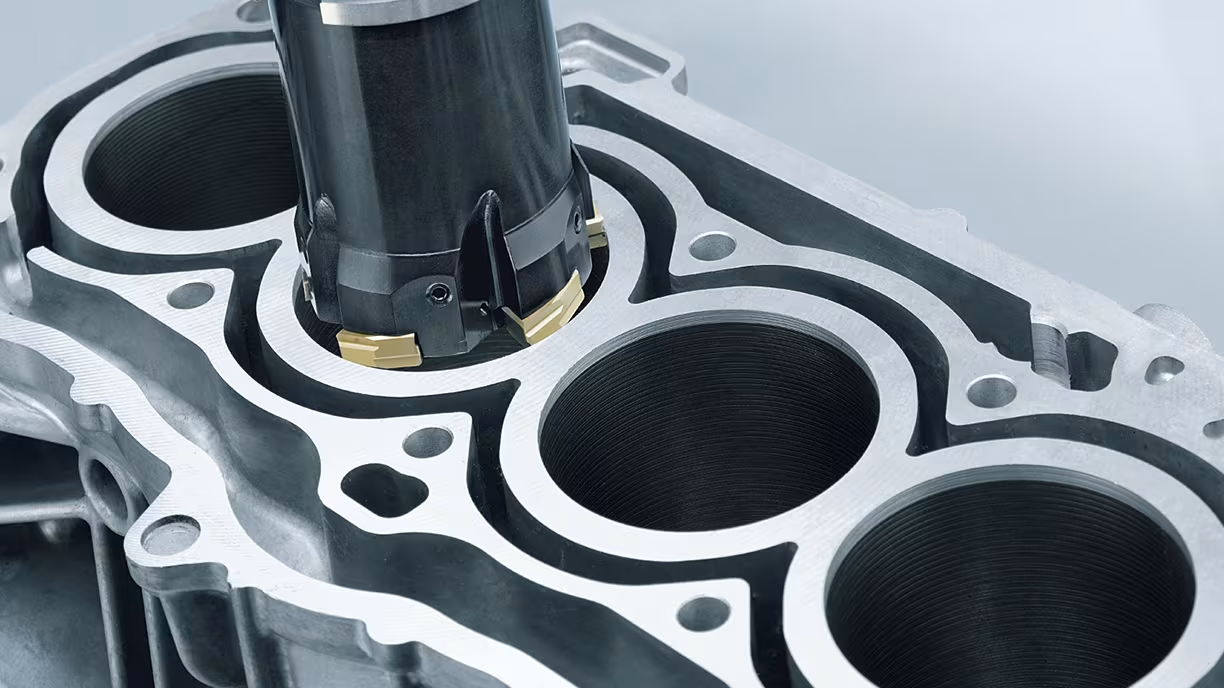

Cylinder Bore Roughing

Setting the pace for shorter processing times: Indexable inserts with multiple cutting edges help create shorter cycle times during roughing. Adjustable systems or monoblock tools are available.

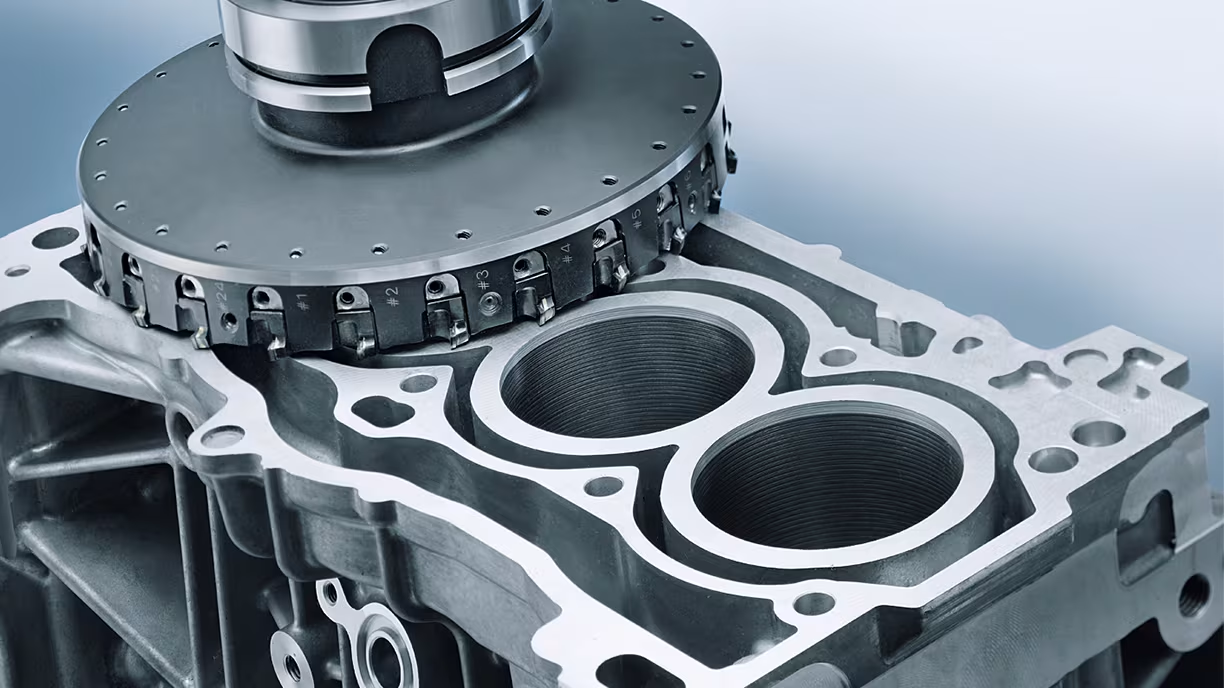

Finishing the Cylinder Head Divider Plate

Defined surfaces and burr-free components are the main goals during face milling processes. LMT Tools secures this level ofquality with the help of adjustable cutting blades and a high number of teeth. Cooling is achieved by means of emulsion, air or minimum quantity lubrication.

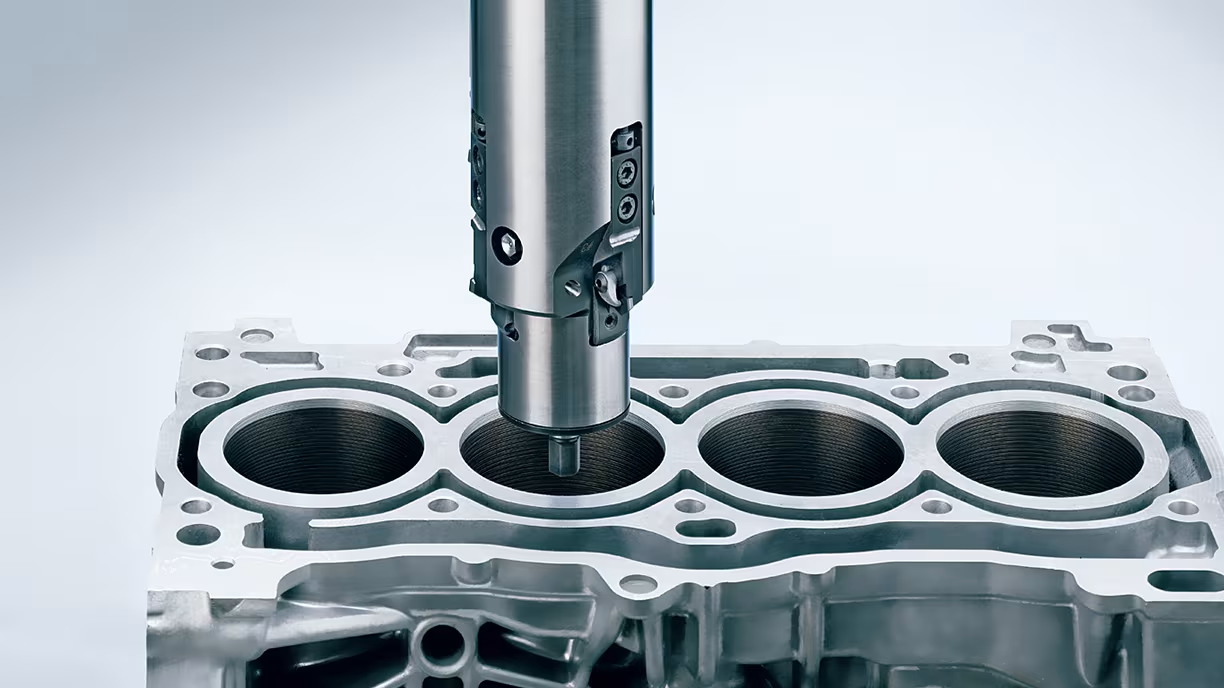

Finishing the Cylinder Bore

The end result must be a bore with a perfect surface and cylindrical shape. To achieve this, the tools from LMT Tools guarantee grooveless processing during each phase of the process (including the return path). The semi-finishing and finishing processes are carried out with a single tool.

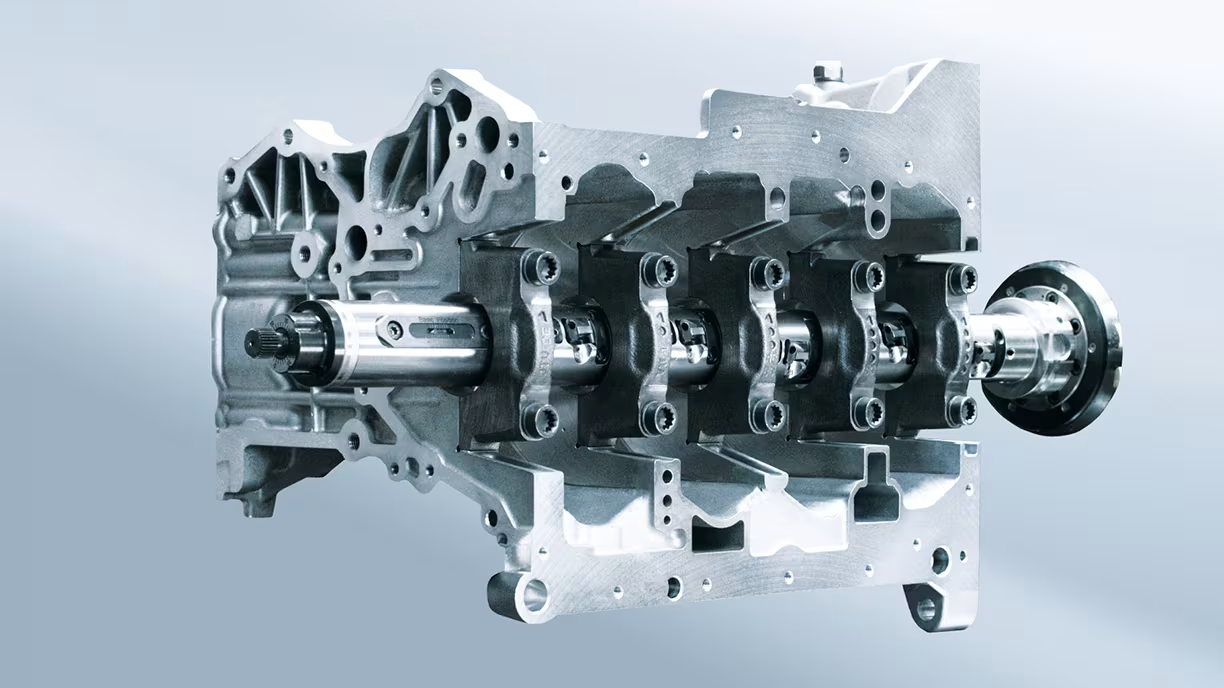

Fine-Machining the Crankshaft Bearing Bore

Maximum surface quality and roundness, minimal cycle times: Tool systems from LMT Tools stand for long-lasting perfection in the finishing of bearing bores. Wear and tear is compensated for with the help of automatically adjustable cutting blades.