Cylinder Head

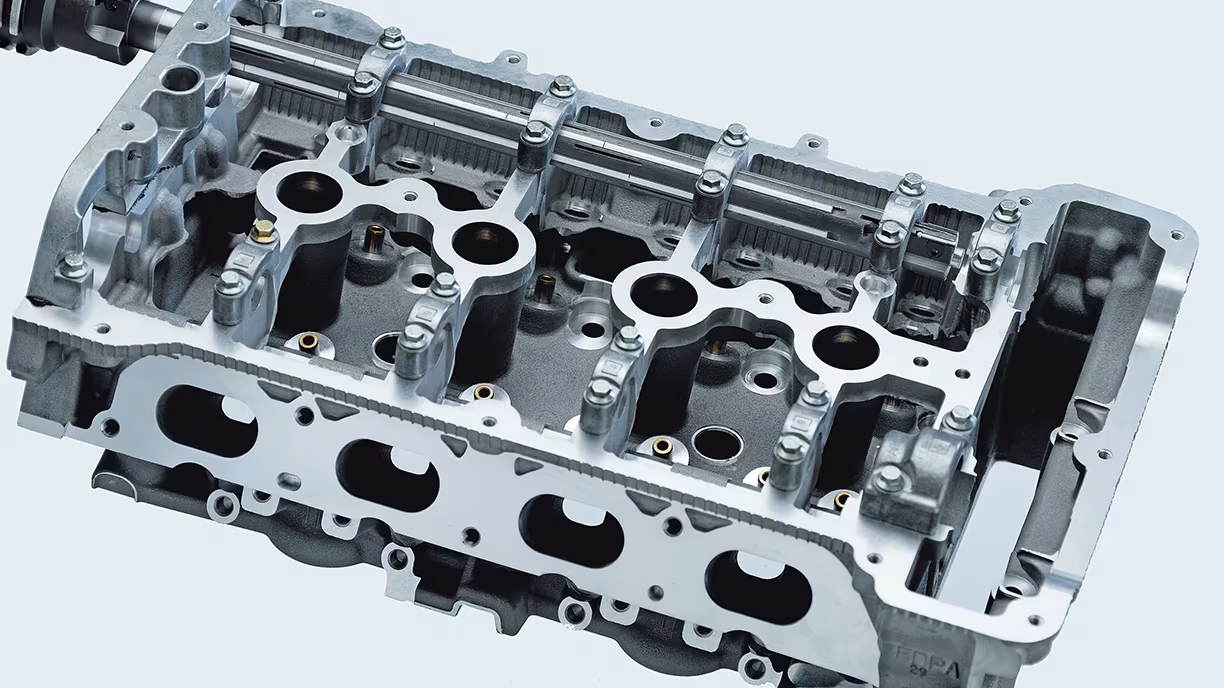

The Challenge of Downsizing

The Challenge of Downsizing

Eight-cylinder engines are reduced to six cylinders, six-cylinder engines to ones with four or even three cylinders – the engines in the automotive industry are shrinking. This changes the requirements to the cylinder head, which is also becoming smaller. The precise machining of the complex geometry becomes a difficult task.

When experts talk about the “thermomechanical challenges” in modern engines, they are also – and specifically – referring to the cylinder head: There are not many other components that the highly compressed combustion process with its extreme temperatures puts this kind of pressure on. Developers are therefore starting to use new materials and modified geometries to guarantee the stability and tightness of the cylinder head. And long with that, another trend is emerging: Just like the entire engine, the component tends to become smaller. This means that the surfaces and bores to be processed are also smaller. The cutting tools that are used therefore assume an especially important role: they must be able to guarantee extremely precise processes while machining the valve seat, injector bore and camshaft bearing bores – and all that while ensuring short cycle times. To achieve this goal, the LMT Tools experts are working to further develop milling systems, cutting materials and tool cooling systems. They also work closely with the people who use these systems. The cooperation begins during the development phase of the component and continues until an efficient processing strategy has been developed.

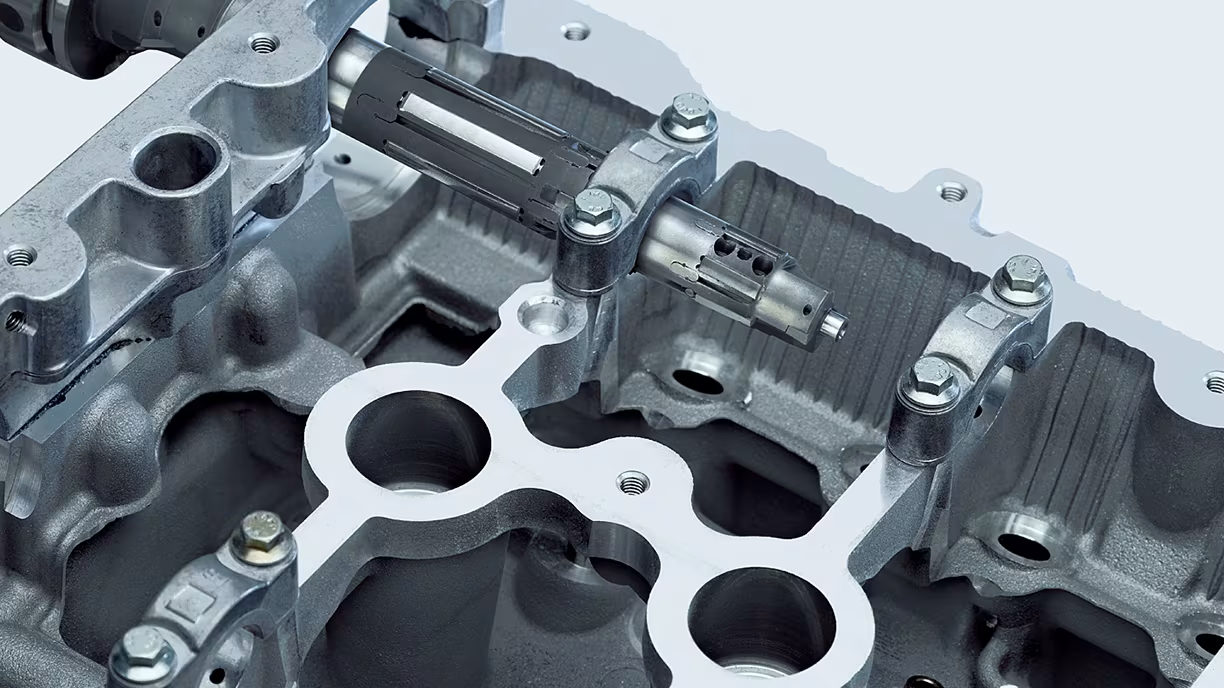

Pilot Bore for the Camshaft Bearing Channel

The pilot bore of the bearing channel must provide a highprecision base for the finish. For this purpose, LMT Tools develops PCD or carbide combination tools for drilling – including cooling and chip removal.

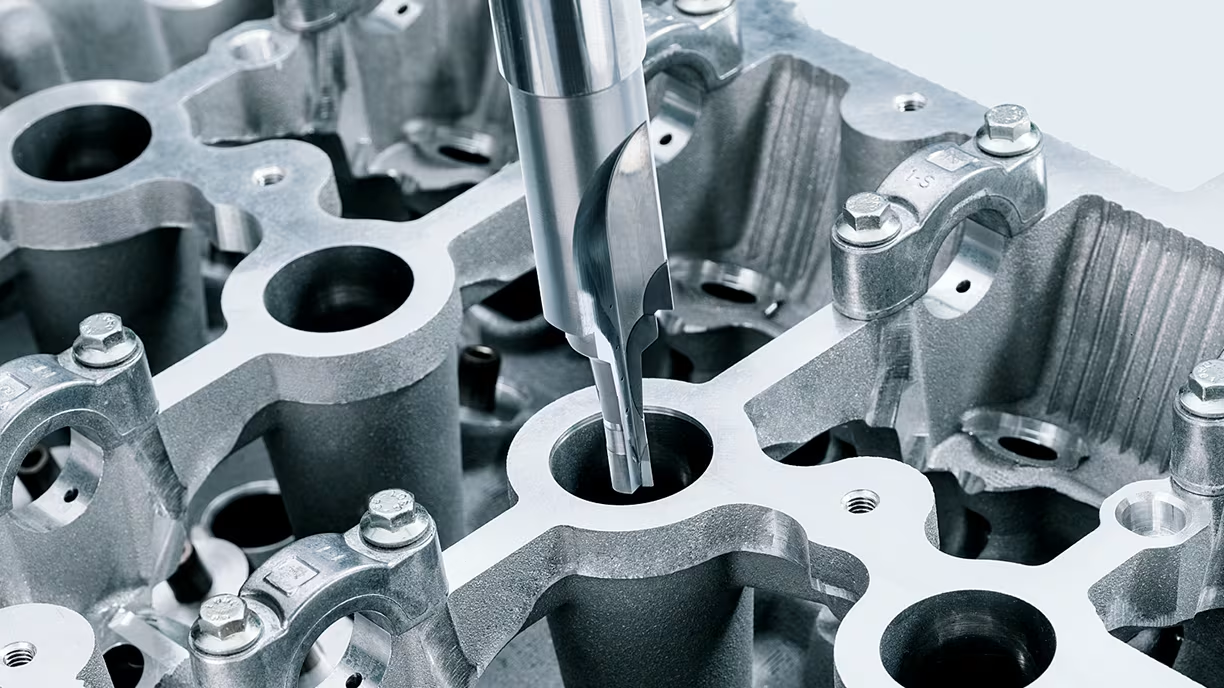

Finishing the Injector Bore

Perfect surfaces despite small diameters: The fine-machining of the injector bore is a special task for multi-stage solid carbide tools with brazed cutting edges made of polycrystalline diamond (PCD).

Finishing the Camshaftbearing Channel Bore

The requirements for the finish are high. The accepted bore tolerance, for example, is only a few micrometers. LMT Tools manages to secure this quality with just two tools. Reamers with single or multiple cutting edges are available to perform the task.

Finishing the Valve Guide and Seat

The finishing of the valve guide is performed in the micrometer range. These extreme values can be realized with the reamers from LMT Tools that feature single or multiple cutting edges.