Automotive

Tool solutions that will change technology

Lightweight construction, downsizing, alternative drives – there is hardly another industry facing similar challenges to the automotive sector. As a result, the production process is continuously changing as well. Precision tools play an important role in this context.

Example downsizing: Engines are getting smaller and lighter. This is the only way to comply with the more stringent emission laws. And it does not mean that the motors are less powerful – it may even increase performance. High compression combustion processes inside the cylinders make this possible. The performance of high compression engines, in fact, is even beginning to prompt manufacturers to reduce the number of cylinders in them. This development ultimately affects all components. However, aside from becoming smaller, components also need to be stronger in order to sustain the high speeds and temperatures they are faced with. This is why construction processes employ high-strength materials and new geometrical shapes with an emphasis on stability.

For the tools, this development is a real challenge: While they must be able to process the complex geometry exactly, they also often have to sustain increased temperatures due to the hardness of the material. This environment requires exactly the kind of know-how LMT Tools has to offer. Our specialists develop tool solutions and strategies for large volume production. They make a significant contribution to lowering the costs of your production processes and fulfilling your ever-increasing quality requirements. In addition, our specialists are very familiar with the production processes in the automotive industry.

This page provides an overview of the components LMT Tools offers tool solutions and know-how for.

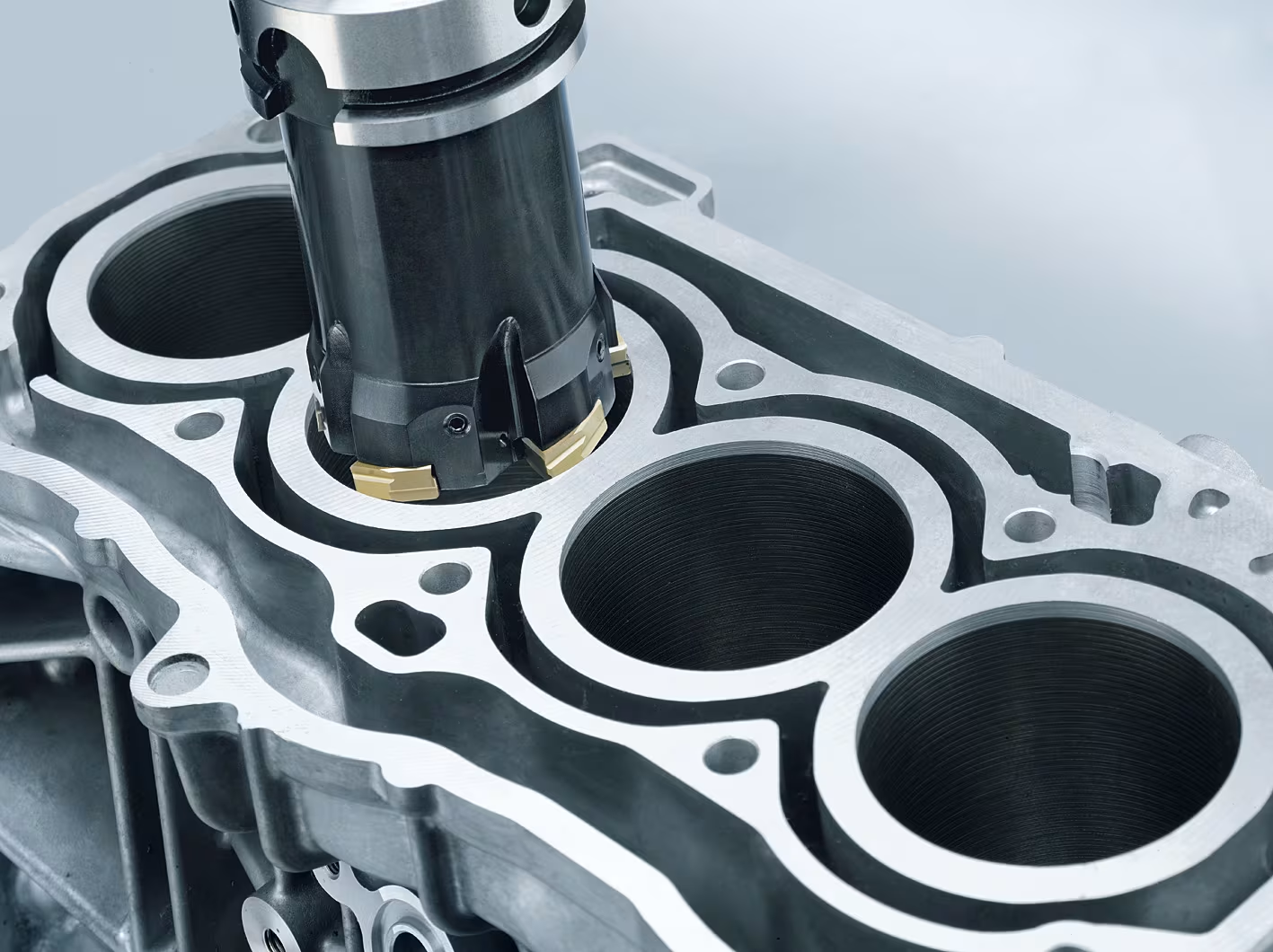

Engine

Cylinder crankcase

Large volume production – accurate down to the last micrometer

Extreme forces are at work inside the cylinder crankcase. The component has to sustain increasing specific forces, such as a high ignition pressure and speed. Only when processed precisely down to the last micrometer can it be guaranteed that the engine is efficient and runs smoothly.

Engine

Cylinder head

The challenge of downsizing

Eight-cylinder engines are reduced to six cylinders, six-cylinder engines to ones with four or even three cylinders – the engines in the automotive industry are shrinking. This changes the requirements to the cylinder head, which is also becoming smaller. The precise machining of the complex geometry becomes a difficult task.

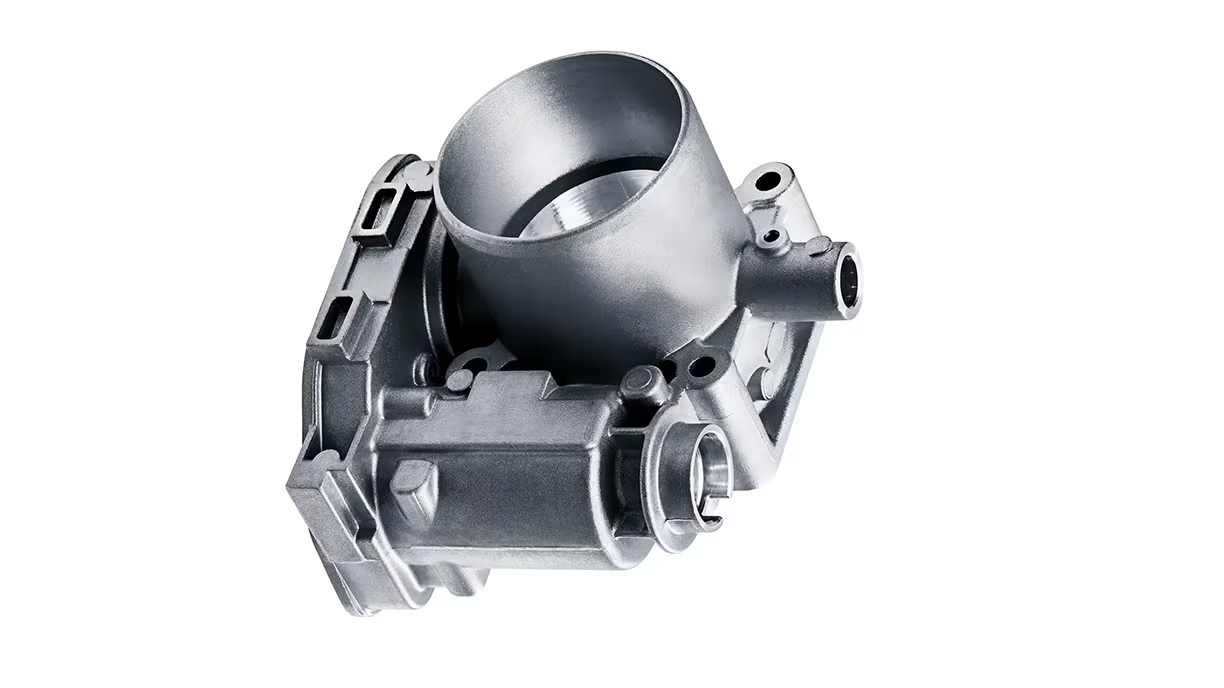

Engine

Engine components

Special challenges for heat-resistant materials

In modern motors, the intake air is compressed even more due to the use of high performance turbochargers. This improves the efficiency of the fuel combustion. The strain this puts on this and other components is obvious. But what does it mean for your chipping processes?

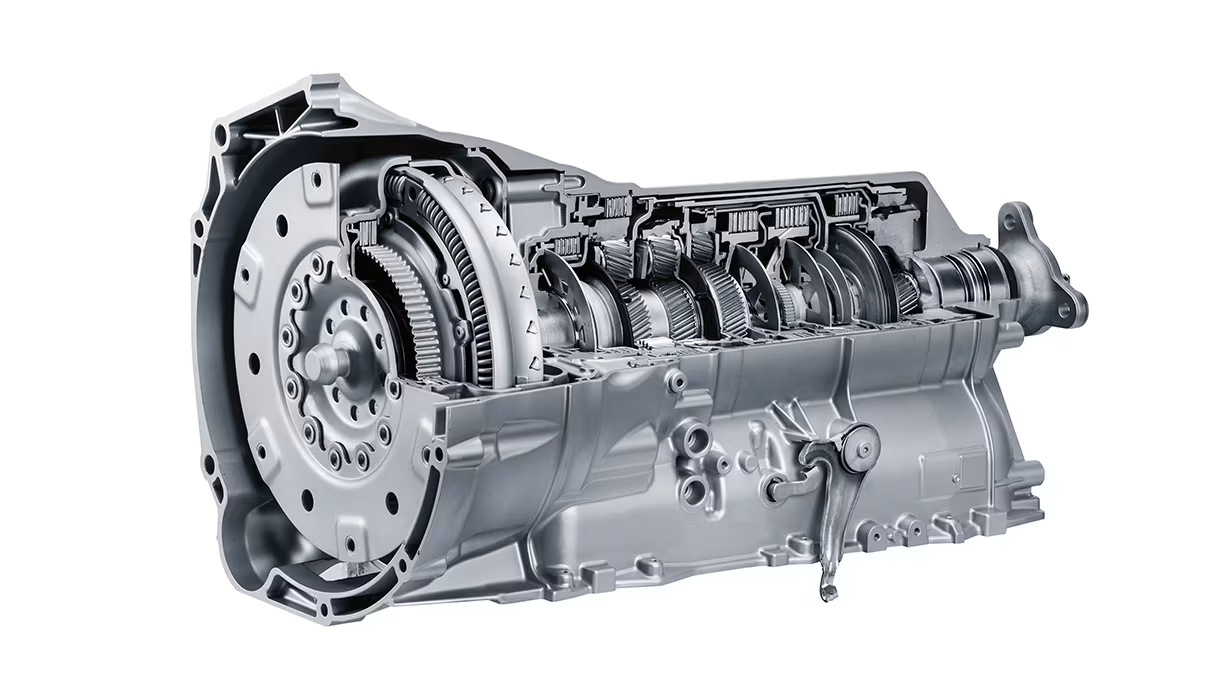

Transmission

Transmission and clutch housing

Thin wall structure – complex shape

Automatic transmissions with eight gears or more are now standard. This ensures that the engine speed range is always ideal, which in turn helps lower fuel consumption in passenger cars. But the weight of the gearbox still needs to be reduced. To achieve this, thin-walled housings are used – a highly sensitive task for the cutting tools.

Transmission

Gear cutting and thread components

Getting your large-scale production processes up to speed

Large-scale production is the key in the automotive industry – large quantities of transmissions and engines are required. Reducing the machining times while securing a high level of process reliability is therefore essential.

Chassis

Steering and chassis components

Maximum precision for stability and safety

In the area of the chassis and steering many innovations have occurred. Electronics and lightweight construction make the vehicles safer and more economical. However, the constant development pressure also affects the production processes of core components.

Drive Shafts

Universal joints

Individual solutions for the perfect geometry

The transmission of engine power largely depends on the synchronized drive shafts: They transmit, for example, the torque from the differential to the wheels and also allow for the movement of the wheel suspension and the steering of the wheels. The main components of these drive shafts are universal joints.

Automotive Downloads

Advanced Tools

PCD Tools

PDF 1.412 MB