LMT Tools with Expanded Gear Cutting Expertise

New Innovations, Solutions and Opportunities

Gear cutting specialist LMT Fette, a subsidiary of LMT Tools, is continuously expanding its range of products and services. New gear cutting tools, innovative solutions, additional manufacturing capacities, and expanded knowledge including the integration of PWS's expertise creates exciting opportunities and real added value for customers.

LMT Fette's gear cutting tools impress with their unique performance, high innovative strength, and unparalleled efficiency, and have long been considered the ultimate in gear cutting. With its passionate commitment to precision, the company ensures that its industrial customers can deliver superior quality at the crucial interface between machine and workpiece. Technological progress and changing customer needs are the most important drivers of innovation.

Expanded Application, Design, and Manufacturing Expertise

“Gear cutting processes are highly optimized these days. At the same time, demands on performance, precision, process reliability, sustainability, and cost efficiency are increasing,” says André Bollow, Head of the Gear Cutting Product Line at LMT Tools, emphasizing: “With our concentrated gear cutting expertise, our wealth of experience, our expanded product portfolio, and our enhanced manufacturing capacities and processes, we now offer customers even greater flexibility in technology consulting, more design customization options, and additional opportunities to further maximize the performance capabilities of our tools.”

Focus on Rolling Shaving and Rolling Broaching

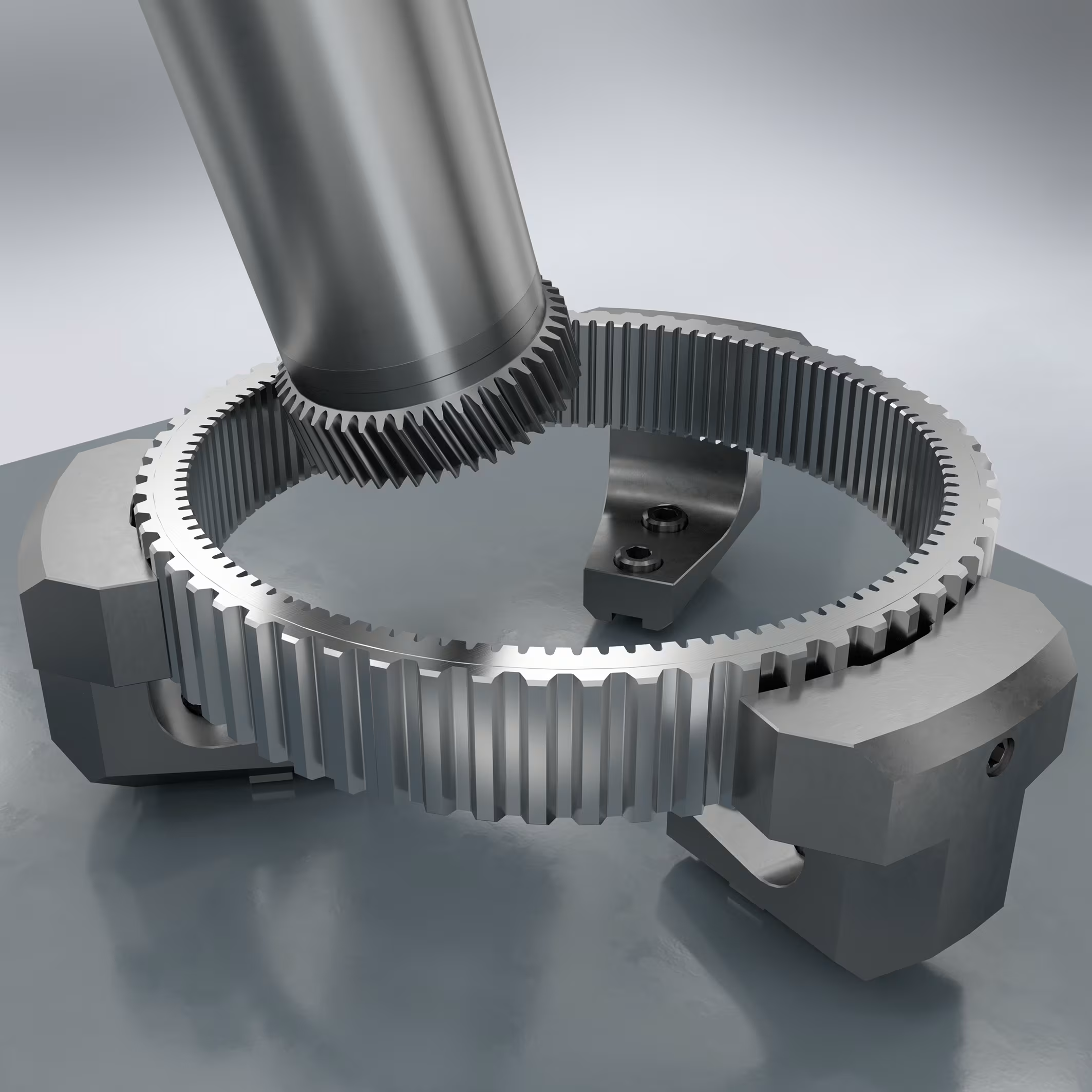

The current focus is on rolling shaving and rolling broaching—two processes that are particularly suitable for internal and external gear teeth with interfering contours. LMT Fette's strengths include special profiles and high-precision quality requirements that must be met with both cylindrical and conical tools. Specifically, Hobbing is becoming increasingly important thanks to its advantages in terms of productivity, quality, and efficiency. For example, the necessary gear modifications in electric drives in the automotive industry cannot be produced with the high quality required using conventional broaching methods. The gearing specialist supports rolling shaving with high-performance, process-reliable tools and specially developed simulation software – all from a single source.

New Peeling and Cutting Wheels

The LMT portfolio includes cutting wheels for gear shaping made of PM material, peeling wheels for gear peeling made of PM, solid carbide, and indexable insert versions, tools for gear peeling with modules from 0.5 to 8, hobbing tools with modules from 0.8 to 12, and indexable insert peeling wheels with modules from 3 to 8. Aviation, automotive – with a focus on BEV gear teeth – mechanical engineering, and robotics are important areas of application.

Technology Consulting and Tool Solutions from a Single Source

"The new products complete our range of gear cutting tools with geometrically defined cutting edges. In addition, we are now able to cover larger module ranges. This means we can now also manufacture tools with a module <1 mm,“ explains André Bollow, adding: ”We implement the optimal solution for our customers' application-specific needs and get the best out of every process with customized tool and process design."