NEW: EASYTap - Universal Tap with Perfect Chip Removal

Top Quality Meets Cost Efficiency: The new EASYTap from LMT Tools combines outstanding performance, maximum flexibility, and highest efficiency in one product range, enabling powerful thread machining in a wide range of materials. A universal tap for reliable thread production in blind holes and through holes.

The EASY product range from LMT Tools includes universal plug-and-play tools for a wide range of manufacturing processes and applications. It combines strong performance, high efficiency, versatile use, and easy handling – bringing together performance, quality, functionality, and cost-effectiveness in the best possible way. With the latest addition, EASYTap, the tool specialist is now expanding its EASY series with a solution for precise and efficient thread cutting.

Excellent Thread Quality with Reduced Tool Costs

The new EASYTap was developed with the key challenges in thread production in mind. It is characterized by perfect chip removal, long tool life, a wide range of applications and maximum process reliability and enables a significant reduction in time and costs in production. Users benefit from excellent thread quality, fast machining times, reduced tool changes and low costs per part.

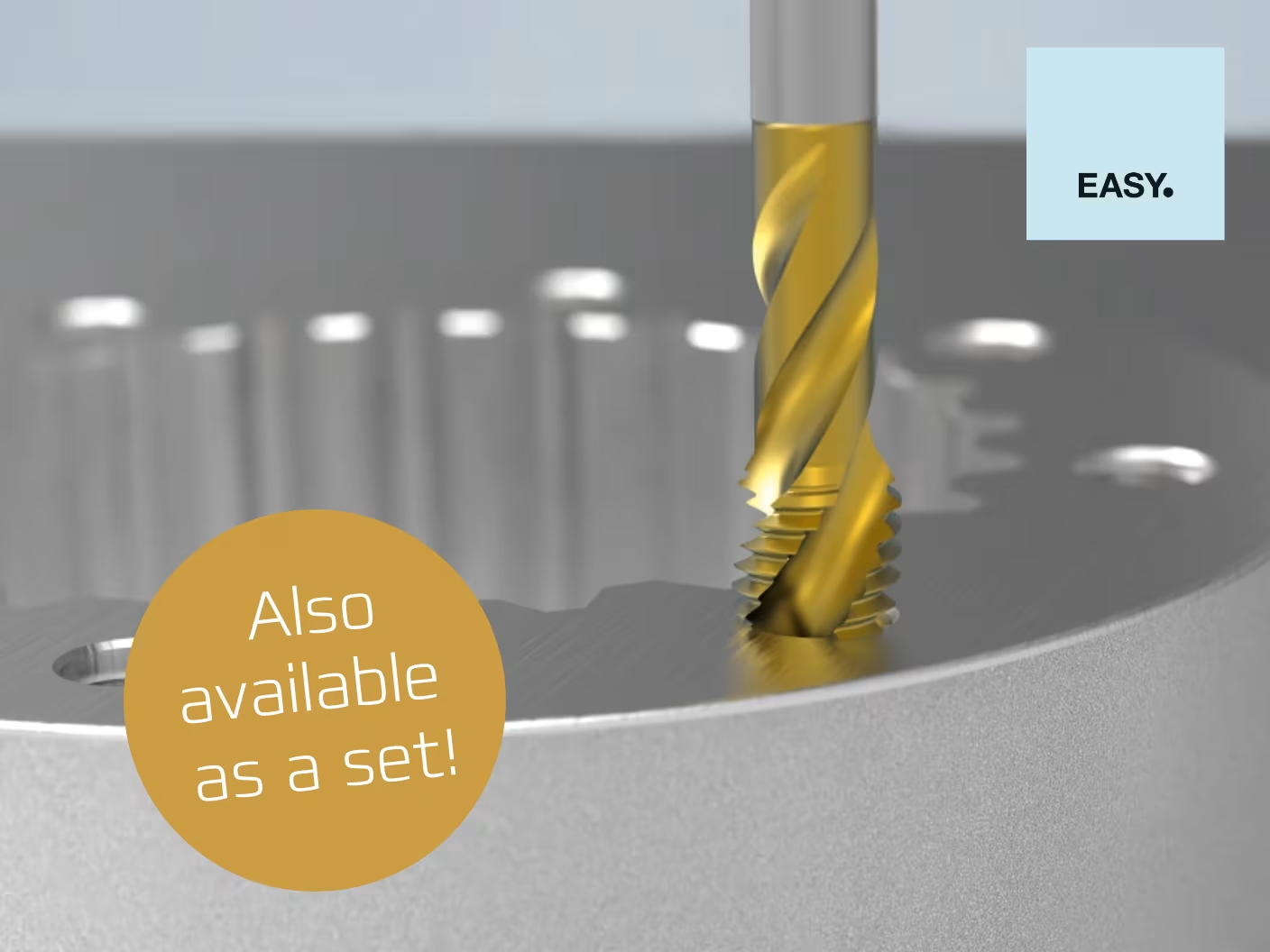

Manufactured from high-quality HSS-E material and finished with a proven TiN coating, the EASYTap guarantees maximum precision and durability. A newly developed lead geometry, optimized flutes and a helix angle of 45° ensure stable and efficient chip formation without chip wrap. The uniform and low torque has a positive effect on tool life.

Top Results in Every Material

The EASYTap produces threads containing gauges up to 3xD and covers a particularly wide range of applications. It is suitable for blind holes and through holes, can be used in almost all materials - be it steel, stainless steel, cast iron or aluminum - and enables the production of all common thread types such as metric standard and fine threads, UNC, UNF, NPT (blind hole), G and EG-M. The standard range covers diameters from 1 to 30 mm / 1 inch. Larger diameters or other lengths can be requested. The EASYTap can be used universally in synchro and compensating chucks or collets and is compatible with oil, emulsion and MQL (minimum quantity lubrication).

Flexible Universal Tap with Outstanding Performance

Whether general mechanical engineering, transportation, drives, cranes, wind energy, die and mould making or pump and valve technology: the EASYTap is a true universal tool and impresses with outstanding results. In a blind hole application with a thread depth of 12 mm in martensitic steel, for example, the tap achieved a tool life of 26,500 threads. That's just 0.1 cents per thread. “The EASYTap provides users with a universally applicable tool for efficient thread production. The new tap offers optimum chip guidance and generates the best tool life and high cutting speeds in any material. This enables a significant reduction in process costs with maximum performance,” says Anita Tritschler, Global Product Manager Holemaking & Finishing at LMT Tools, summing up the benefits.