HPC from LMT Tools: New High Performance Cutter for the Highest Demands on Productivity

Schwarzenbek, 11. May 2023 - LMT Tools is one of the most renowned experts in the development and production of precision tools and regularly sets technological trends in the market with its high innovative strength and tool expertise. The latest coup: new high-performance milling cutters for high-performance cutting. The HPC family combines the proven DHC Premium, DHC INOX Premium, DHC Slot and DHC Hardline tool series all under one cover and, thanks to improved technology, achieves a significantly higher metal removal rate. Considerable increases in productivity with optimum process reliability are thus guaranteed.

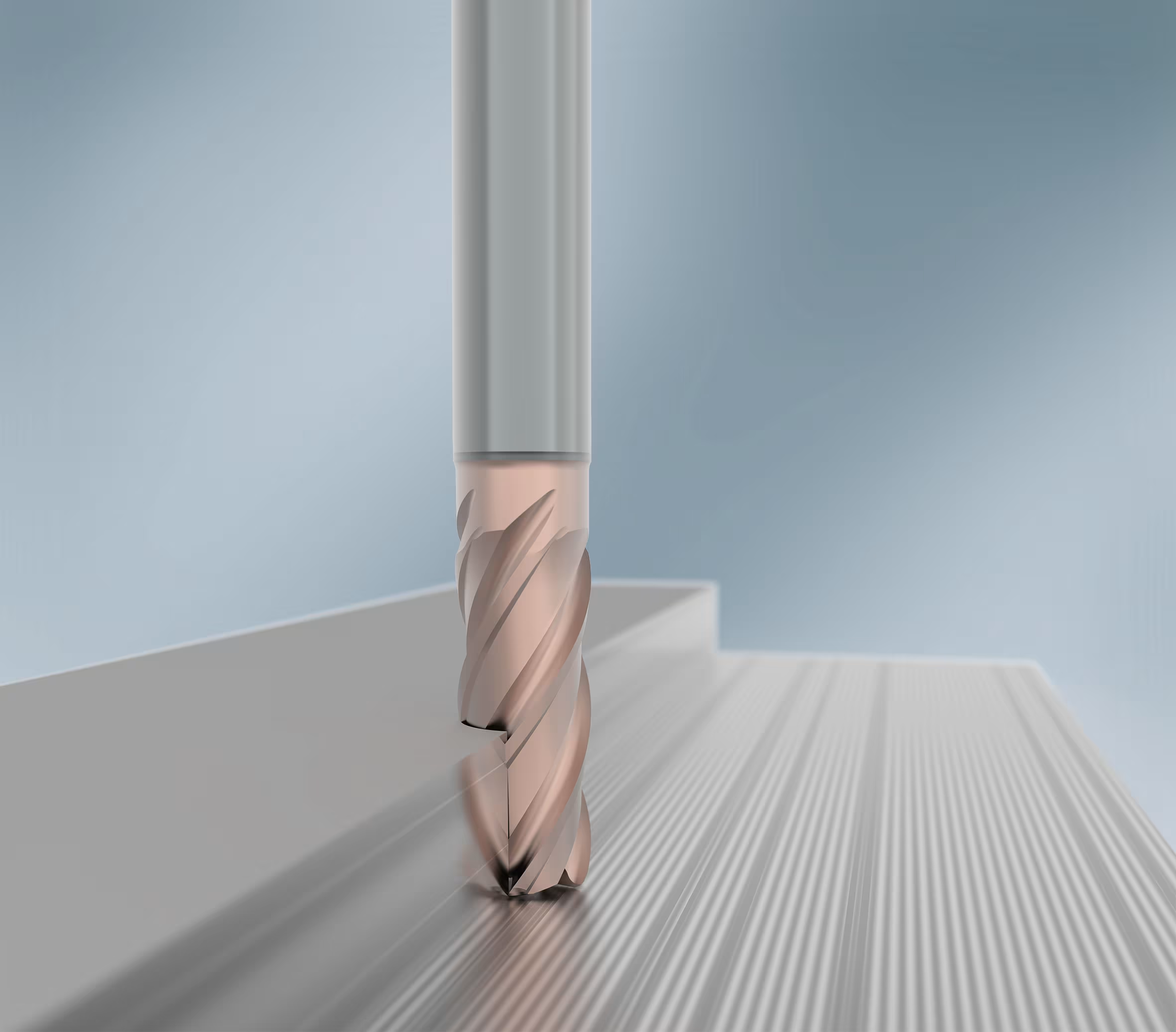

High Performance Cutting (HPC milling) requires high-performance tools that can optimally withstand the strains caused by the high cutting speed and feed rates involved in the process and ensure cutting with as little vibration as possible. With the new HPC family, tool expert LMT Tools offers the perfect solution. The cutting geometry, coating and cutting-edge treatment have been specially adapted to the special requirements of high-performance machining and enable maximum metal removal rates and high dimensional accuracy with first-class surface quality. The unequal pitch ensures maximum smoothness and process reliability, while the surface quality of the machined workpieces is a further advantage.

The Optimum High Performance Cutter for Every Material

Whether trochoidal, side, corner and groove milling or ramps up to 0.5x diameter - the HPC family is designed for a wide range of applications. There are four versions available: HPC P, HPC M, HPC UNI and HPC H. The HPC P is the specialist for higher alloyed steels and castings with a tensile strength of 900 N/mm2 or higher. An edge protection bevel reduces the load on the cutting edge and ensures optimal performance in the demanding machining of abrasive materials. The HPC M excels in the machining of austenitic steels, non-ferrous metals and titanium. The positive cutting-edge geometry and special coating ensure efficient machining of materials that usually have higher toughness and are therefore difficult to machine. The HPC UNI is a three-flute cutter (while all other variants have four flutes) and therefore provides a larger chip space. Thanks to its excellent chip removal, it is ideally suited for full slot milling in a variety of materials (P, M, K, N and S). Each flute has a different helix angle. The HPC H is the best choice for hardened steel up to 55 HRC. Its targeted edge rounding results in a particularly stable cutting-edge, allowing for very high feeds in hardened and high-strength materials up to 1,600 N/mm².

Maximum Tool Life and Productivity__

The new HPC family replaces the well-known DHC family. By optimizing production processes and using state-of-the-art technology, tool life and productivity have been significantly increased compared to the proven products of the previous series. "With our new high performance cutters, high cutting speeds and feeds can be achieved. The result is a high chip volume and increased productivity," says Marcus Paul, Global Head of Product Management at LMT Tools, and emphasizes: "Compared to the proven products of the previous families, we have managed to increase the metal removal rate by more than 30% and achieve a tool life increase of up to 70%." This once again underscores the technological leadership of the tool experts at LMT Tools.